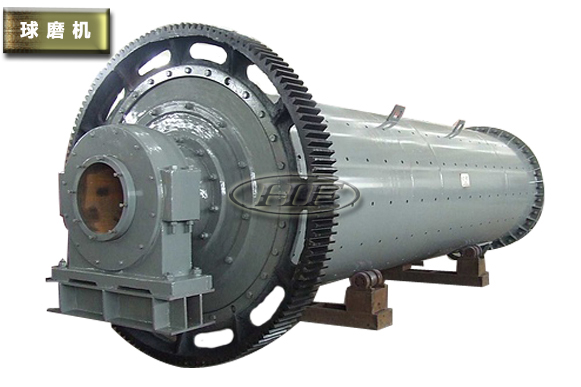

ball mill

ball mill detailed introduction

we're usingaerated block equipmentIn the process of producing aerated blocks, the ball mill is mainly used for the treatment of white ash, which has the advantages of high efficiency and stable equipment. The whole grinding system generally consists of jaw crusher, bucket elevator, block lime storage bin, vibrating feeder, ball mill, dust collector and other major equipment.

ball mill working principle:

we are inAerated Concrete Block Production Lineis a horizontal cylindrical rotating device with external gear transmission, two silos and a lattice ball mill. The materials from the feeding device through the feeding hollow shaft spiral evenly into the first bin of the mill, the bin is equipped with a stepped lining plate or corrugated lining plate, and the steel balls of different specifications are filled in. When the cylinder rotates, centrifugal force is generated to bring the steel balls to a certain height and then fall down, crushing the materials in the cylinder. In addition, there is a grinding effect between the grinding bodies. The materials are continuously added by the front bin and rotated together with the cylinder to form the extrusion of the cylinder, after the first warehouse reaches rough grinding, it enters the second warehouse through the single-layer partition board. The warehouse is inlaid with a flat lining board and steel balls to further grind the materials. The powder is discharged through the discharge grate plate to complete the grinding operation.