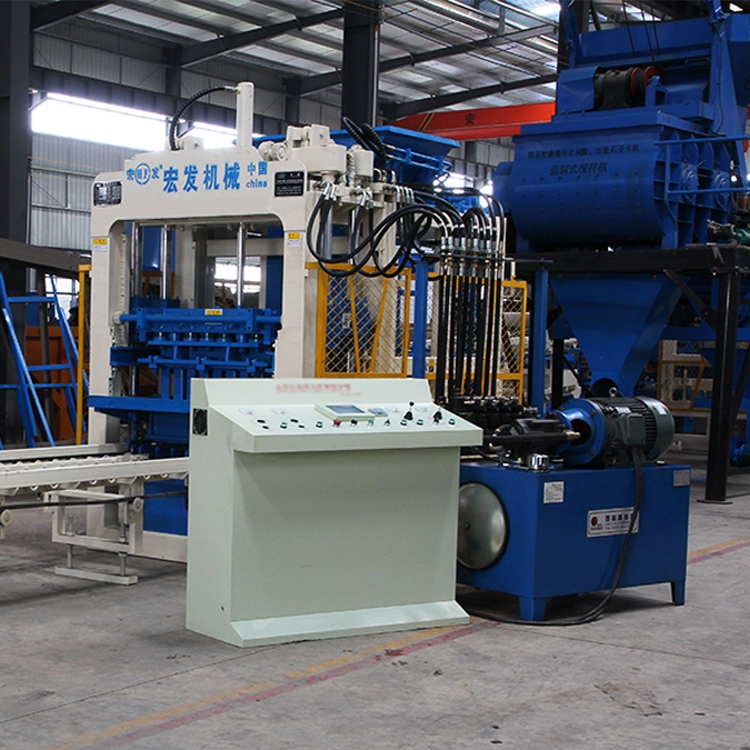

QT6-15D type cement brick machine

The QT6-15D block forming machine developed and produced by our company is a special equipment for the production of building blocks. The machine can use fly ash, slag or other industrial waste residue and river sand, gravel, cement and other materials, through the replacement of mold production of a variety of different specifications of the hollow block, porous brick, curb stone, road brick and grass brick, ring tree brick, slope protection brick and other concrete products. The fabric-matching mechanism can also produce layered products..

QT6-15D block forming machine adopts a gantry frame structure, which is strong and resistant to vibration and has good reliability. The design adopts the hydraulic discharge mode of independent foundation, and the raw materials are put immediately. Mesh wave type swing cloth structure, cloth effect is good. The plug-in welding mold is made of manganese steel carburizing and quenching. The 100000 mold is not easy to deform and wear. The QT6-15D block forming machine can form a simple production line with PLD1200 batching machine, JS500 mixer, 8 m belt conveyor, and palletizer.

QT6-15D type automatic hydraulic brick machine features:

1. This machine is a comprehensive technical equipment of mechanical, hydraulic and computer automatic control. It is characterized by high efficiency, reasonable design, compact structure, simple operation and convenient maintenance.

2. The block forming is mainly mechanical vibration, supplemented by hydraulic pressure, and completed by vibration pressure. The compressive strength of the block products produced can reach more than 15MPa (MPa), with high compactness, good frost resistance and impermeability, excellent sound insulation, heat insulation and heat preservation performance, and accurate dimensions.

3, integrated oil system, high life, low energy consumption design.

4. Operation mode: It has different automatic and semi-automatic operation modes to ensure uninterrupted production.

5, variable frequency stepless speed regulation, to achieve a reasonable operating speed, accurate deceleration braking and positioning.

6, database system: intelligent services, can record, reset, save, file, warning, processing, print reports.

7, self-test function: failure can be automatically diagnosed to ensure production safety.

8, metering control system: high precision, automatic centralized control system.

main technical parameters:

(1), machine dimensions: 7160 × 2000 × 2800mm

(2), rated pressure: 21 Mpa

(3). Main vibration form: Taiwan vibration

(4), vibration frequency: 2800-4500 times/min

(5), vibration acceleration: 15-20g

(6), exciting force: 60kN

(7), pallet size: 8800x680x25mm

(8), product height: 50-200mm

(9), molding cycle: 15-20 s

(10), overall power: 34 kw

(11), overall quality: 7000kg

(12), production of main product specifications and output